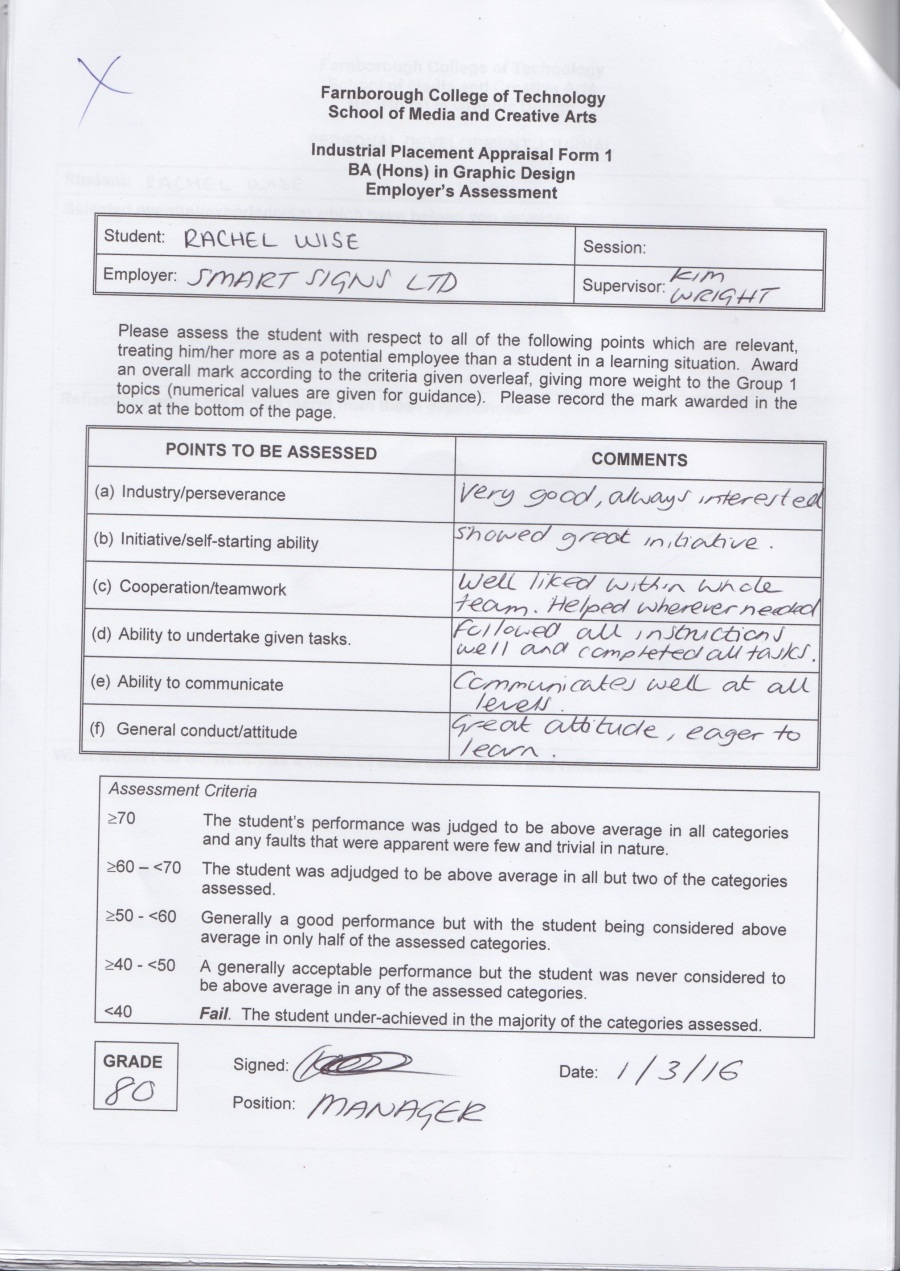

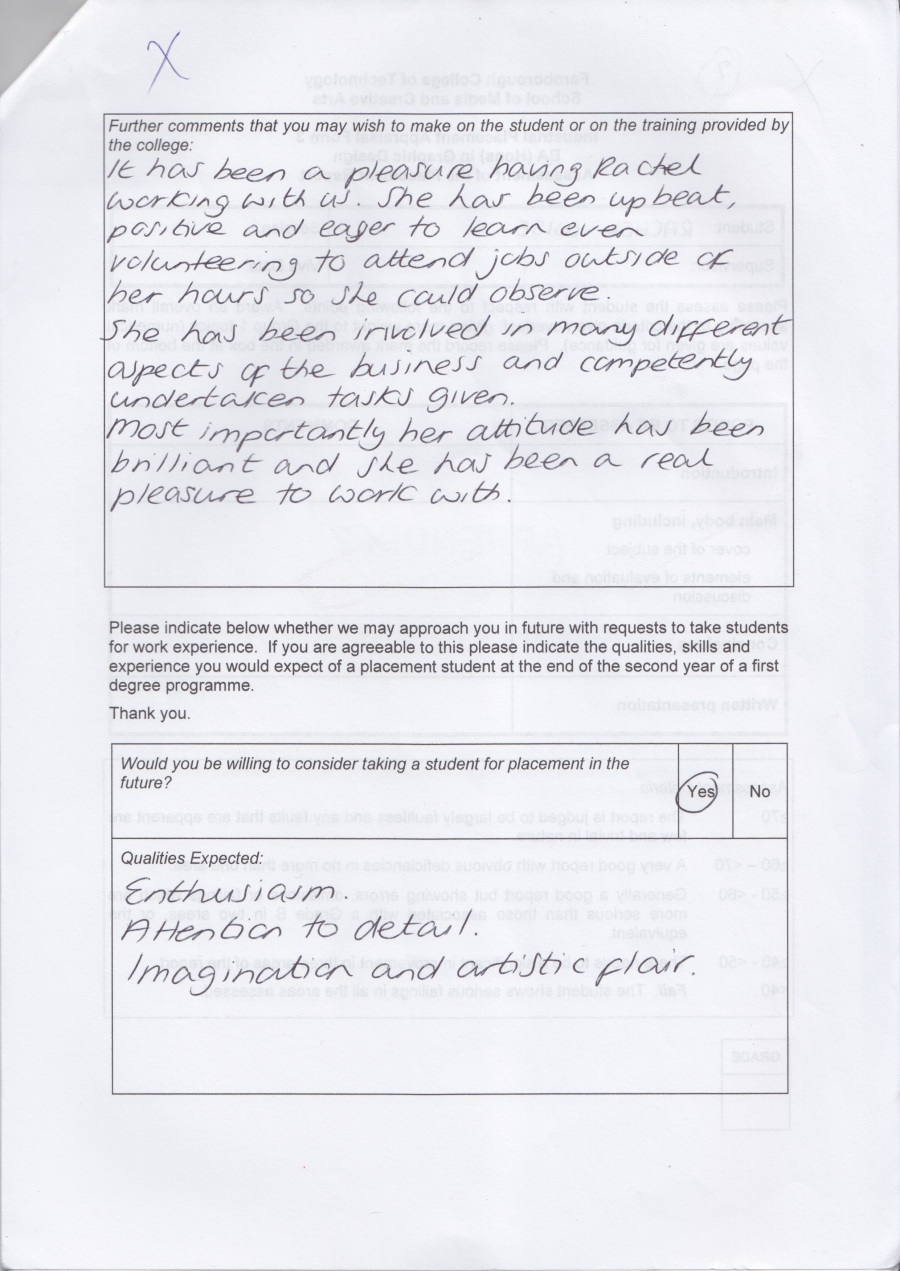

I started my first day at Smart Signs on 26th January. In their Bracknell branch there are four people; James, Kim, Val, and Amy. James is the owner of the company and covers design work and going out to survey jobs that people have asked him to do. Kim is James’ girlfriend, and she does all the accounting, ordering, very little design work, and a little production work. Val is James’ mum, and she does all the production work, cutting vinyl, creating mugs, coasters, and using high tech cutting machines and materials to make frosted glass and other things. Amy does the majority of the designs and the art work for clients that come in.

Because the company is so small, everyone has to pitch in where they are needed. There is another branch in Southampton of three people, one covers the accounts and stuff that Kim does at Bracknell, and there are two other guys there who do the production work and designs.

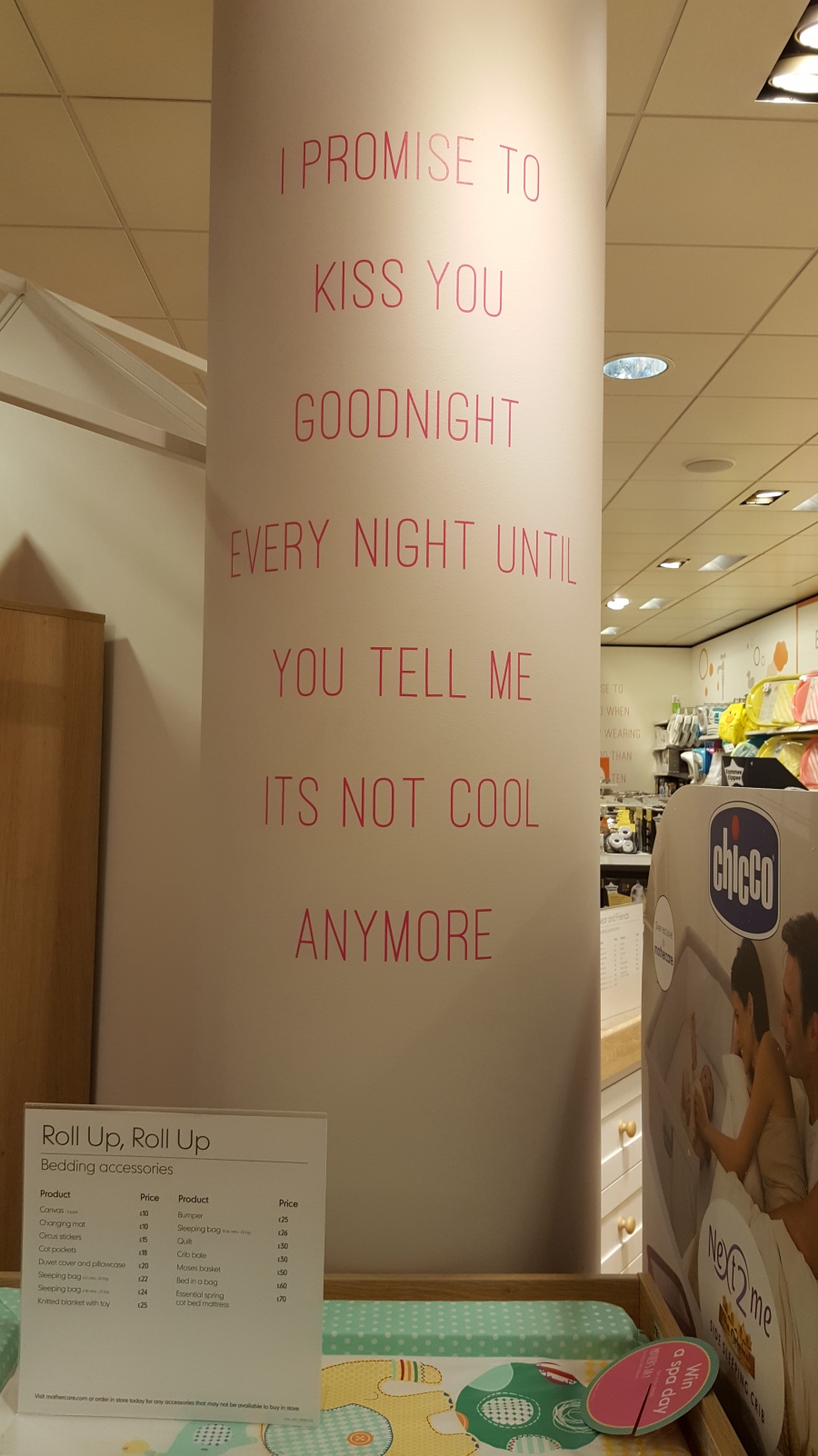

They have some really big contracts with shops like Mothercare, and companies like Reed. They do a lot of shop windows in Oxford Street for some big names. A lot of people come to them for things like office equipment, and signs for their windows or frosted glass. They also cover all the car vinyls for a lot of driving schools; an example is Blue School of Motoring. They use Adobe Illustrator as their main software for doing everything on.

The type of organisation that Smart Signs is a Sign & Graphics company.

Some of the equipment there is very big and can be difficult to use, such as a laminator, industrial guillotine, vinyl cutter, and flat letter cutters.

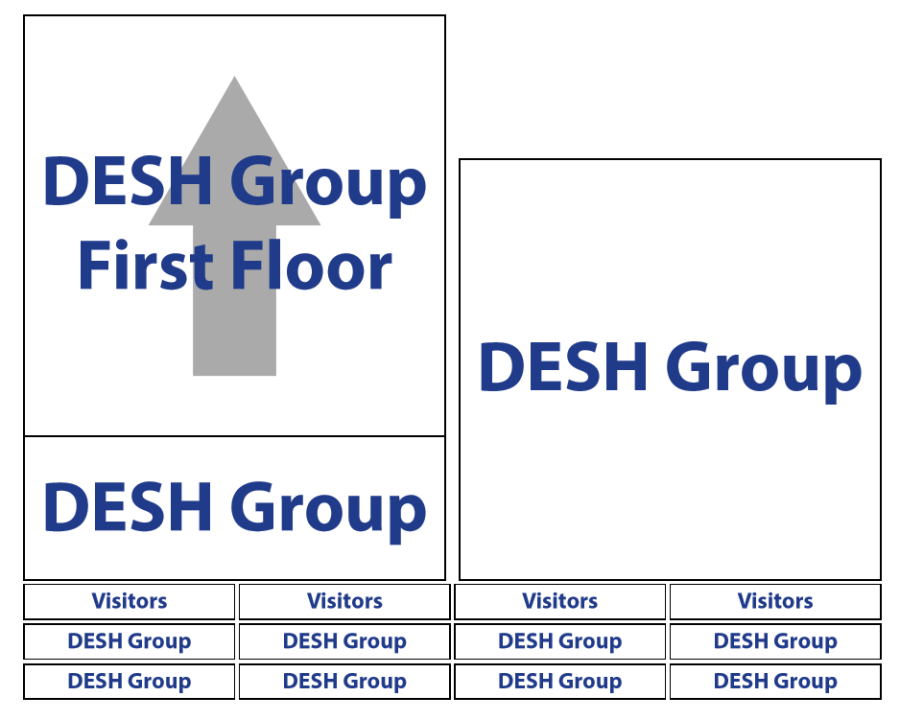

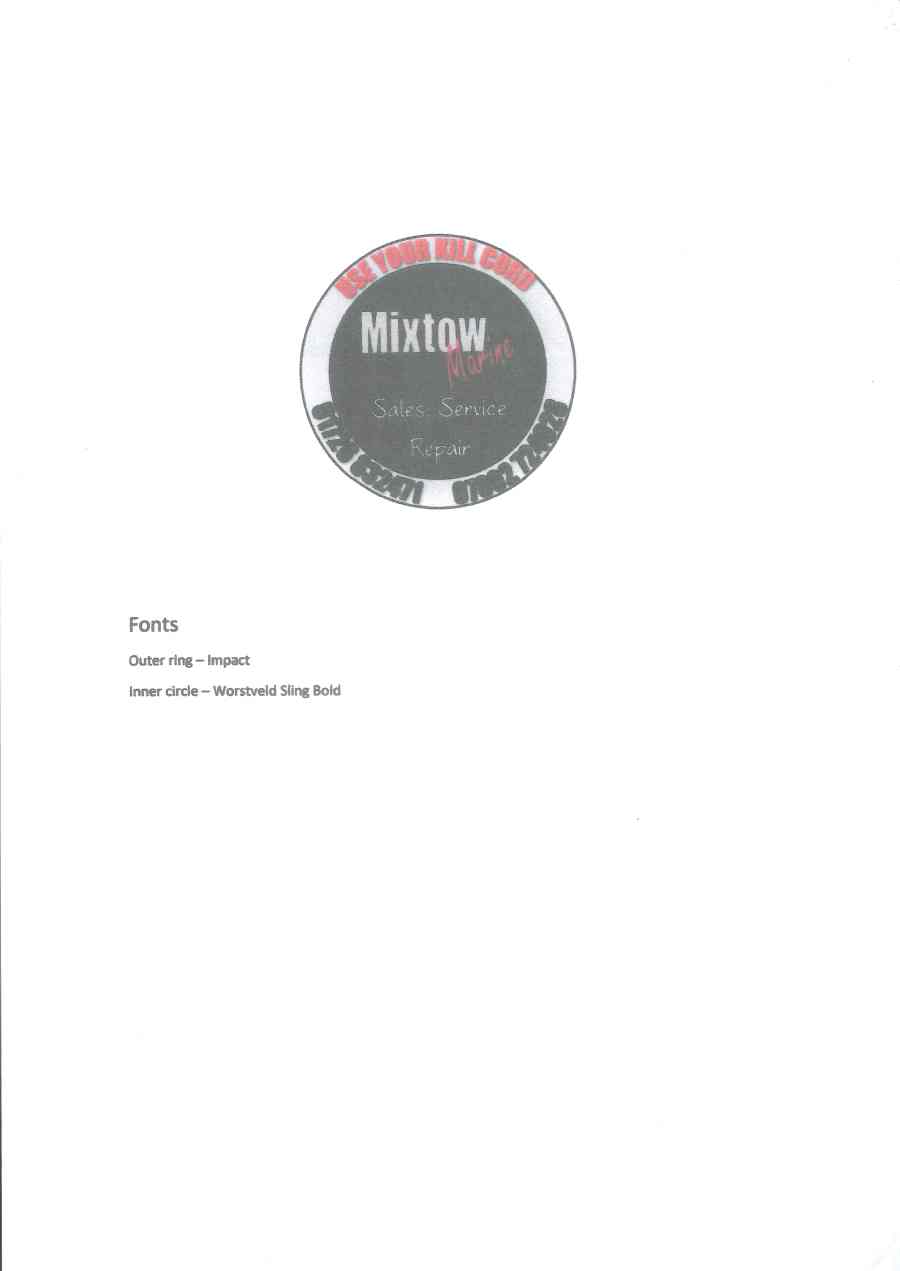

A man came in about a previous piece of design done by the company and asked for it to be reworked into, so I was given the task of doing so to meet the client’s expectations. I changed the text to match the logo of the company as the design that was previously done did not match it at all. It was for a round sticker and they wanted to logo on the top of the circle and the telephone numbers in a clearer text on the bottom.

Before:

Amy’s Design:

My design:

I was shown how to use the industrial guillotine and all the safety precautions before you are supposed to use it. You cannot cut your fingers off because the machine does not work unless the cover is closed.

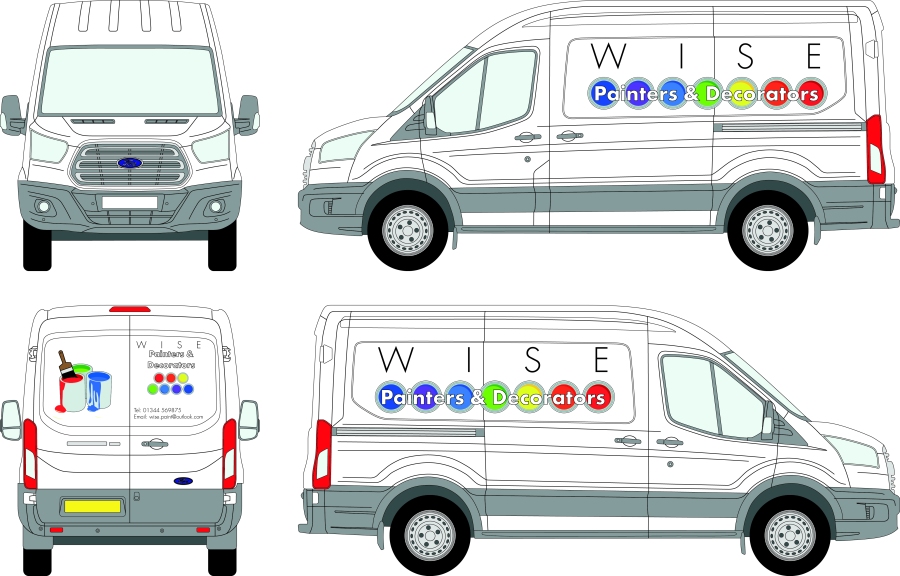

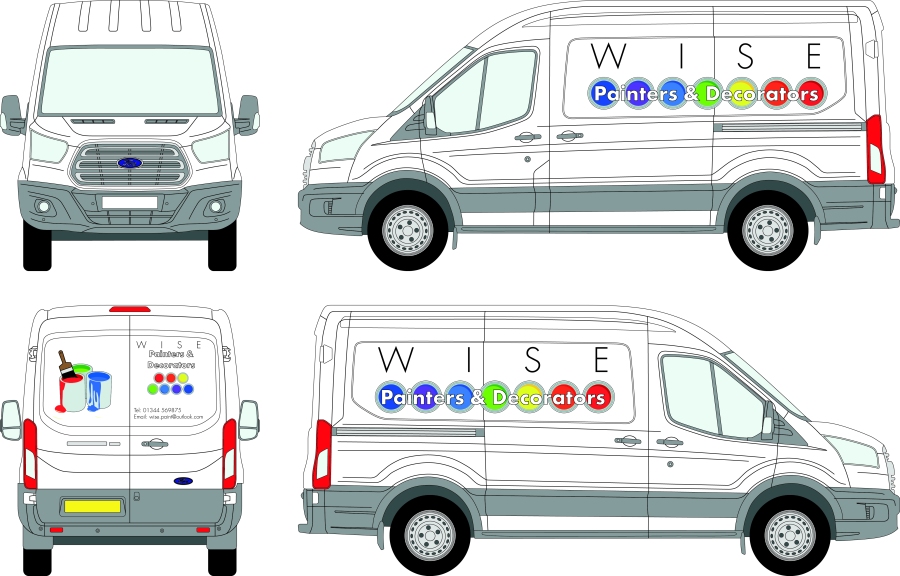

Kim wanted to see what my Adobe skills were like so she asked me to design a vinyl for a van on a preloaded van template that they have on their system, based on a labour company, so building, painting, decorator, carpenter etc. I used Futura Light as my font and used some of their clip arts to make the logo up and added an email, and contact telephone number on the back. Kim was really happy with it and thought it was great that I designed it so quickly. James was in a meeting at the time so when he came back I showed him my van design and he was really pleased with it and was also impressed on how quickly I came up with the concepts.

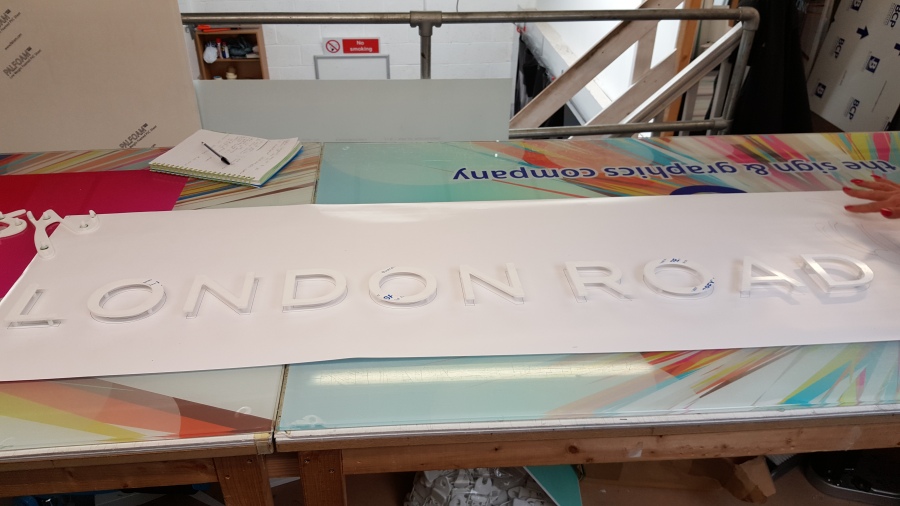

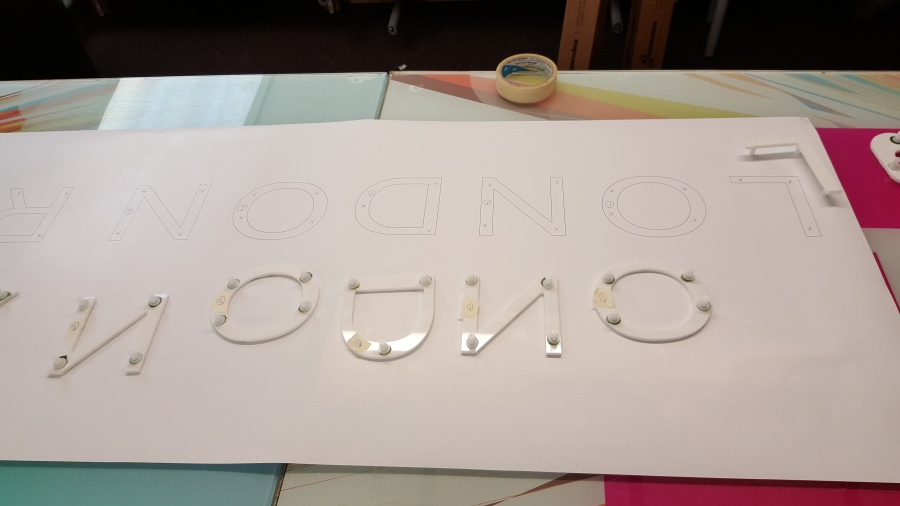

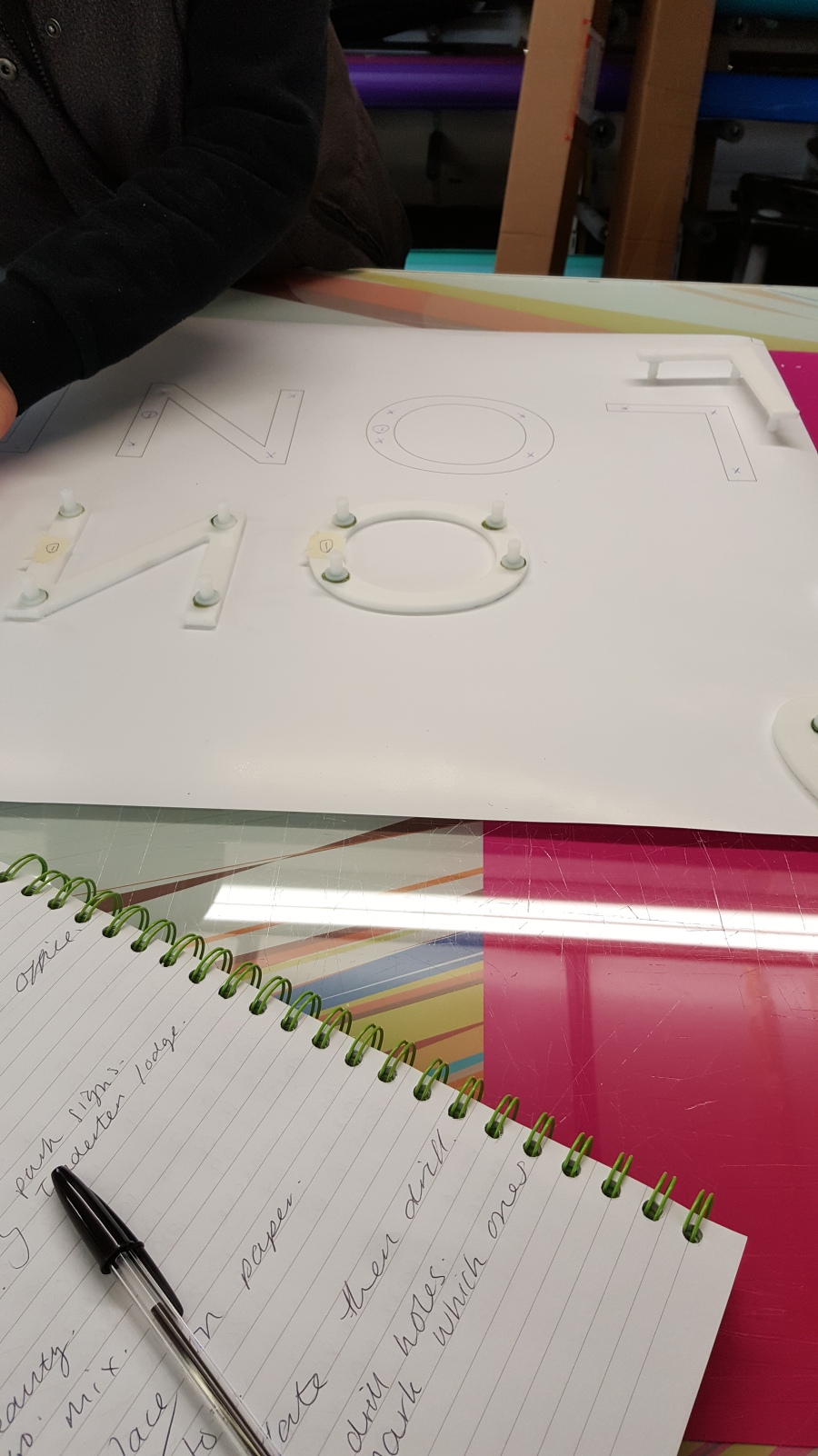

I went upstairs with Val and we looked at how to make frosted glass wrapping for a Reed shop front in Staines. We used Illustrator to create the boxes the right size for the window and programmed it to the “Summa Cutter” which would outline the boxes on special paper so that we could then peel off the frosted parts and place it on the window.

James also tasked me with redesigning his business card because he didn’t like his one.He thought is was too big and the squiggly line underneath his name wasn’t straight. My advice to him was to make the text smaller and put the address on the other side so that it isn’t with the logo. I came up with four different designs for him and he said he liked the fourth one best so now that is his new business card.

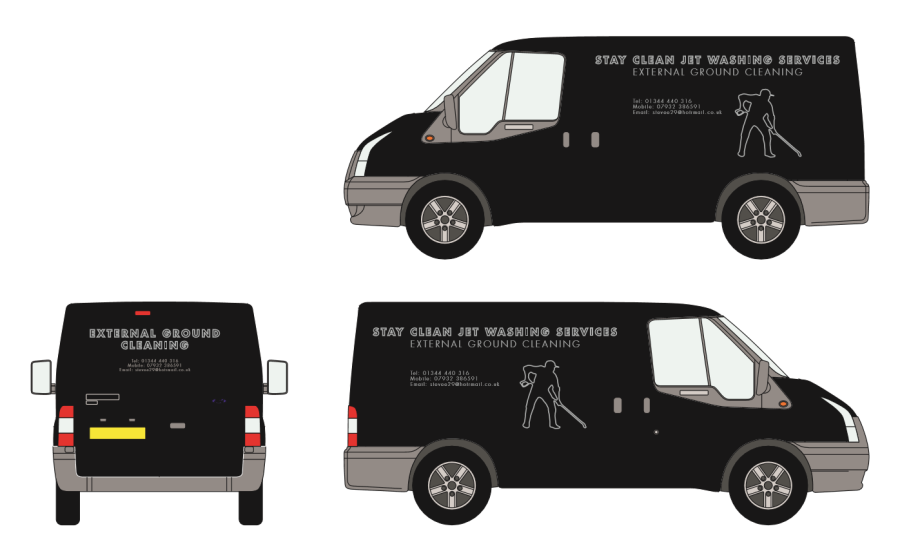

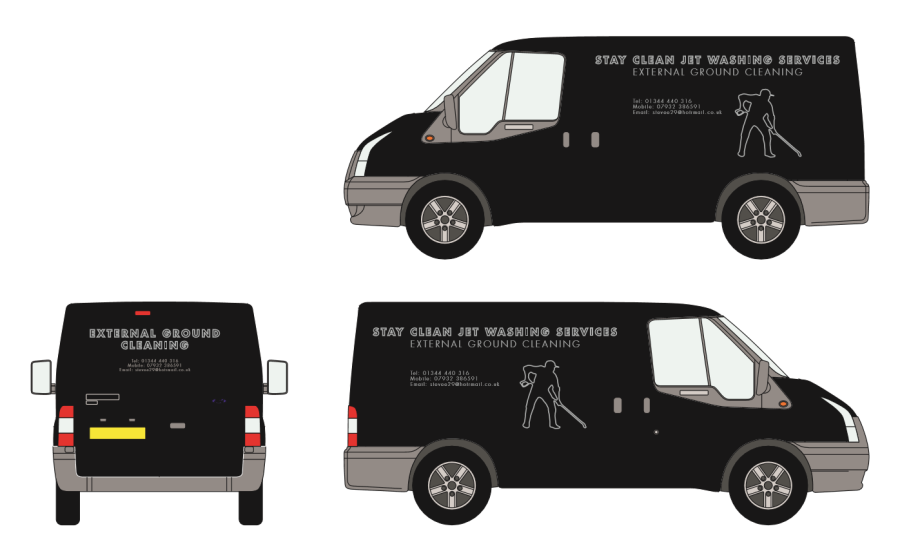

A group of men came in and asked for a design for their company which they wanted to be called “Stay Clean Jet Washing Services” and reiterated that it would be for external floor cleaning. They left their mobile, office, and email information with us and James asked me to have a go and come up with some designs for them. I came up with 4 concepts and made it unique. It was for a black transit van and they wanted to use either white or grey for their vinyls so I chose to stick with those colours. Within 20 minutes I came up with the four concepts, and yet again, James and Kim were pleased that I designed them so quick.